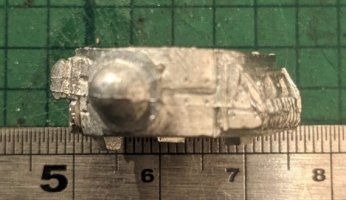

With the callipers I make it:

Between 8.2 and 8.9mm tall (varies a bit around the edge)

The ring is 20.5mm in outer diameter, noting that the greeblies make it thicker in places.

The bottom of the ring has an inner diameter of between 18 and 18.2mm.

The ledge in the bottom of the ring has a conical hole starting at 14mm and going down to 9.9mm

The top ring nubs are 2.2mm thick and 3.6mm wide and protrude 1.5mm above the top of the ring.

The top fo the ring has an inner diameter of 16mm and immediately slops down to the 9.9mm centre hole.

The arm half domes vary from between 6 to 6.5mm in diameter, they are mounted on plates 7.6mm in diameter and 1mm thick.

The arm domes protrude 2.3mm from the plates.

The two rear main plates are 8.6 and 9.2mm wide respectively and ~1mm deep, the little boxes on them are 5.4mm wide and 4mm tall and 1.3mm deep.

The front baffle is 13.3mm wide where it affixes to the ring and 10.3mm at the front. It is 6.6mm tall where it affixes to the ring narrowing to 2.8mm at the grill.

I now have an overwhelming urge to go and get one of the offcuts of 20mm pipe from the garage and make one! Alas I have work to be getting on with. However if I do have a minute and you don't have any suitable bits lying round I can try to cut out a few 9mm tall rings of conduit and post them over (assuming you are UK based) as a base to work on - as long as you promise to document the build here!

Personally I'd probably overlay with a thin rolled out layer of green stuff (or whatever you modelling material of choice is) and stick that all over and carve the main panel detail into that. Once dry I'd do the main rear panels out of a bit more green stuff and likewise for the front grill panel. I'd roll a ball for the arm nubs and cut that in half, trim a bit more off (they are under a full half sphere), tidy it up shape wise then let those dry. Then make up some disks for the arm mounts and fix the half balls into those.

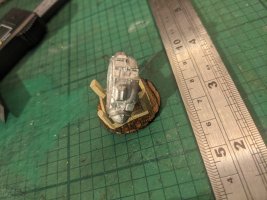

Some photos attached (sorry some the focus is a bit out ...)